ADVICES TO USE CUTTING MACHINES :

The reasons of the bad functioning of a cutting machine could be as follows :

- The bad condition of the saw because it must be sharpened or has got broken teeth. Therefore, the cut will not be correct and the machine will warm up in excess because it will be working with more power than the due one.

- The machine is not lubricating correctly. After the cutting, if the profile is totally dry, it means that there is a lack of lubrification. The machine will warm up in excess and the cut won’t be well executed. Therefore, it is necessary to verify:

- The level of lubricant.

- The good functioning of the venturi (if it is obstructed, it must be cleaned).

PROCEDURE OF MAINTENANCE :

To ensure a perfect condition of functioning, it is suitable to follow the following standards :

- Clean of shavings and others cuts from the interior of the tool without allowing that they should accumulate.

- To lubricate columns, knifes and other mobile parts of the tool by means of a lubricating or similar spray.

- To verify from time to time the edge of the cutting elements.

- Don’t work doing lever with the profiles of aluminium on the punching supports since these might end breaking. The profiles must be introduced straight on.

- To keep the tool when it is not employed in a dry place. Pulverize some type of antirust product.

- In case of having some incident with the tool or if you need some spare part, please contact INDUSTRIAS AZ S.L..

SAFETY STANDARDS OF PUNCHING TOOLS :

In order to guarantee the safety of the user , it is OBLIGATORY to fulfill the following standards :

- The place of work where the tool is in use must be perfectly illuminated and with the sufficient space for the managing of the profiles to mechanizing.

- The use of the tool is individual.

- The presses which will be used with the tool have to fulfill the regulation “CE" of safety. If you see some deficiency in the same ones, don’t use the tool until this one is solved.

- The coupling and the fixing of the tool in the press must be done of rigid and sure form, by means of bridles.

Important :

- If the press is AZ mark, the patent coupling ensures a total security and a correct functioning of the tool. However, if it’s another mark, please verify if the coupling is correct.

- Be careful when you introduce the profiles during mechanization by keeping the hands far from the work area. Be careful when you touch mobile parts of the tool, extract shavings. Use if possible pincers or other similar tools but never introduce the hands.

- Never manipulate the tool under pneumatic supply. The cleanliness and the maintenance must be done out of the place of work.

- Never strike the tool.

- Use necessarily protective gloves.

- Industries AZ S.L. doesn’t take responsibility of the accidents that could be caused of an undue use of the tool or of a foreign modification from the manufactured product at our factory.

FUNCTIONING AND MAINTENANCE OF PRESSES :

Instructions of installation :

- LEVELING : it’s important to get a perfect leveling of the machine. It must be on a flat surface and in good condition to obtain a perfect functioning.

- LIGHTNING : the lightning is very important to obtain a major quality of work. The natural light is better. Nevertheless, it is not always sufficient. That’s why, it is necessary the use of artificial light with enough intensity.

- LOCATION : The machine has to be in a dry and hot place. It must be separated from the walls as well as of other machines for a minimal distance of 80 cm. If it is closed to a corridor, no mobile piece or profile don’t have to invade the corridor.

Use of the press :

The press must be connected to the pneumatic supply with a flexible pipe of 8 mm. to the spike of the right side of the manometer according to the figure.

The press works by means of a pedal with protector:

El accionamiento de las prensas se realiza mediante un dedal con protector:

CONNECTION 1 GOES TO THE FILTERING GROUP (opposite side to the one of the spike).

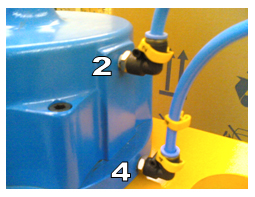

CONNECTION 2 GOES TO THE LOW PART OF THE CYLINDER (SEE FIG. A).

CONNECTION 4 GOES TO THE HIGH PART OF THE CYLINDER (SEE FIG. A)

FIG. A

Precautions and contraindications :

Precautions and contraindications :

This machine has been designed according to the safety standards in accordance with the European regulations of security on machinery (98/37/EC) and its subsequent amendments.

Nevertheless, it is essential to follow a set of rules to obtain more security :

- Read carefully this manual.

- Do not place your hands inside the machine. The operation is carried out using a pedal.

- Use always safety gloves.

- It is suggested to use hearing protection.

- When the use of pneumatic machines, don’t exceed 8 Kg/cm2 pressure.

- Don’t manipulate the security protections and keep them in perfect condition. In case of wear, replace them.

- Periodically check the condition of the machine and especially protections. Regularly lubricate its moving parts.

- Wear appropriate dress (not too wide, especially at level of the sleeves) to avoid clashes, don’t wear accessories which can cling to the moving parts of the tool.

- Ensure the cleanliness of the moving parts.

- Please keep away children and make sure that no unauthorized person can handle the machine.

- Find a comfortable and natural working position. Don’t work in places unsuitable for the handling of the machine.

- Be careful when the work requires repetitive and monotonous operations. Don’t ignore your own safety.

- It is forbidden to use air pressure when cleaning the machine for security reasons.

- This machine was designed for use on aluminium carpentries lines and must be handled by qualified and trained staff since the user will be the only responsible for any damage due to improper handling.

IMPORTANT

Don’t manipulate mechanical parts when the tool is connected to the pneumatic supply.

Spare parts :

1) Filtering group REF. FRL14

2) Pedal REF.PEDAM500

3) Elbow fitting 1/8 tube 8 REF.GMC150818

4) Elbow fitting 1/4 tube 8 REF.GMC150814

* NORMATIVAS:

* NORMATIVAS:

All presses manufactured by INDUSTRIAS AZ S.L. are certified in accordance with the European regulations of security on machines and comply with the following standards :

- Directive 98/37/EC, 22 June 1998 “Safety on machines”.

- Directive 93/68/EEC, 22 July 1993 "Amendments concerning the Directives 73/23/EEC and 89/336/ EEC".

- Standard UNE EN 292-1, "Safety of machinery; basic concepts, general principles for design; part 1: basic terminology, methodology".

- Standard UNE EN 292-2, "Safety of machinery; basic concepts, general principles for design; part 2 : principles and technical specifications".

- Standard UNE EN 292-2 am. 1 and Erratum, "Safety of machinery; basic concepts, general principles for design; Part 2: "Principles and technical specifications. Amendment A1 ".

- Standard UNE-EN 294 "Safety of machinery. Safety distances to prevent access to dangerous areas by the upper limbs”.

- Standard UNE EN 811, "Safety of machinery. Safety distances to prevent access to dangerous areas by the lower limbs”.

- Standard UNE EN 953, "Safety of machinery. Protections. General requirements for the design and construction of fixed and movable protections".

- Standard UNE EN 1050, "Safety of machinery. Principles for the assessment of risk".

OPCIONALES

REGULACION DE CARRERA: ES UNA PIEZA OPCIONAL, Y QUE SIRVE PARA AJUSTAR LA CARRERA DE LA MATRIZ, SE AHORRA EN EL CONSUMO DE AIRE, CON NUESTRAS MATRICES NO ES NECESARIO POR QUE VIENEN CON FINAL DE CARRERA.

MAINTENANCE FC-300 :

The copy router machine works with single phase 127V with a router bit of ø 5 x 60 handle of 8.

The FC-300 is not a machine of production. In case of excessive use, the machine could warm up and would stop working. If due to several overheatings, the functioning of the machine is not correct, you must proceed to the cleanliness of the cupper bar and the brushes.

In order to clean the brushes, you have to do it with a moistened rag with alcohol. To clean the cupper bar , you have to use a cleaver (please see attached drawing).

CUTTING MACHINE ACAF-400 :

When you open the frontal part, you will see two electrovalves. The one which is in the forward part controls the raise and the descent of the pneumatic cylinders. The one which is in the rear part controls the raise of the saw.

When you open the frontal part, you will see two electrovalves. The one which is in the forward part controls the raise and the descent of the pneumatic cylinders. The one which is in the rear part controls the raise of the saw.

1º Disconnect the coil and the connector from the electrovalve.

2 º With the machine connected to the pneumatic supply but without electrical connection, push on the blue button.

- If the cylinders rise and go down with difficulties, the electrovalve must be changed.

- However, if they rise and go down without any problem, it means that there is an electrical failure.

With the cover down and the machine connected to the electrical supply, please verify with a tester if between the pin 1 and the pin 2 of the connector, there are 24 volts in a.c. (alternating current).

If it’s not the case, the problem could come from the coil of the electrovalve. Nevertheless, if it’s not the coil, the failure could come from the electrical panel (probably the second connector).

Previously it would be necessary to verify all the connections from the red card (with a flat screwdriver).

If everything is correct and the second connector is on, it must be changed. The correct functioning of the machine is as follows :

when the cover goes down, the connector nr. 2 is activated. If you push on the button Q3 (starting of the saw), the connector nr. 1 will be actived as well and the saw will rise.